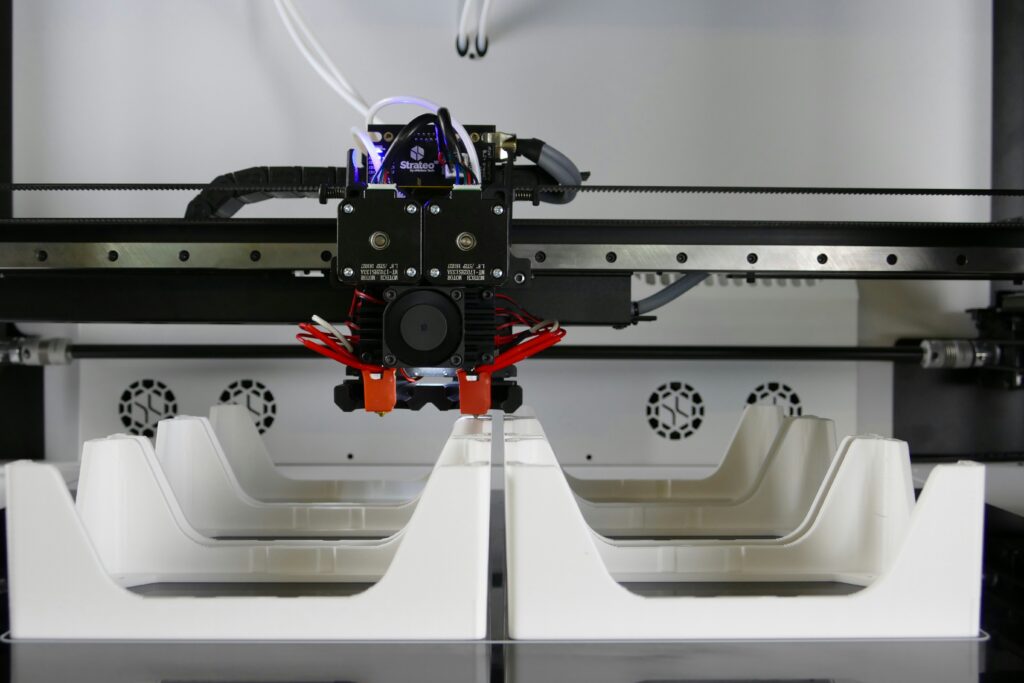

3D printing combined with the R&D phase offers several advantages, such as rapid customisation of prototypes, reducing production costs, optimising processes and reducing material waste.

During the development process, the use of this technology makes it possible to carry out rapid tests and personalised adaptations, adjusting to the specific needs of each area.

3D printing gives Matglow the ability to rapidly iterate on prototypes and test functionalities in real time, significantly speeding up the development cycle. This enables engineers and researchers to experiment with different solutions before moving on to final production. This process not only improves efficiency but also favours the creation of solutions that are better adapted to market needs and technological challenges.